Gas Metering Unit Base

Generatör Uygulamaları için Çift-Yakıt sistemleri ARTEMIS

500 Kw ile 2000 Kw güç aralığındaki küçük ve orta ölçekli tüm yüksek devirli makinelerin tek yakıttan çift yakıta geçirilmesi Heinzmann donanımları ile başarı ile yapılabilmektedir. Yapılmış uygulamalar için referans dosyasına bakmanız rica olunur.

500 Kw ile 2000 Kw güç aralığındaki küçük ve orta ölçekli tüm yüksek devirli makinelerin tek yakıttan çift yakıta geçirilmesi Heinzmann donanımları ile başarı ile yapılabilmektedir. Yapılmış uygulamalar için referans dosyasına bakmanız rica olunur.

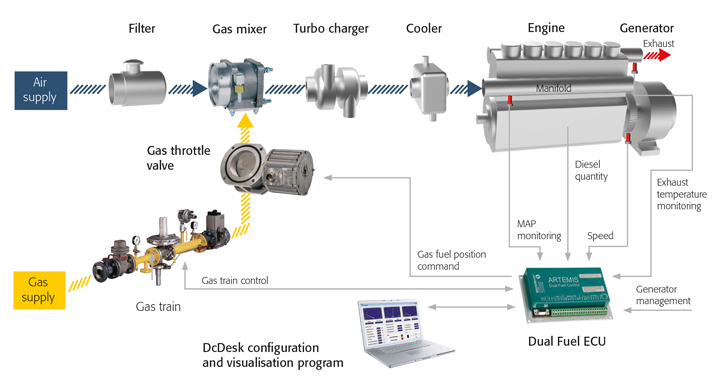

Bu uygulama esnasında makine üzerinde herhangi bir işlem yapılmamakta Heinzmann donanımı makineye aşağıdaki çizimde gösterildiği şekilde ilave edilmektedir. Çift yakıta geçirilen makinenin tüm Heinzmann donanımlarına Türkiyede Ogan teknik tarafından bakım ve servis hizmeti verilebilmektedir.

Dual-Fuel System ARTEMIS for Marine Propulsion Engines

For marine applications, focus is shifting to dual-fuel technology, aiming for a significant reduction in fuel costs as well as compliance with stricter emission standards. The ARTEMIS Dual-Fuel System offers a complete, tailor-made dual-fuel solution based on proven and certified components. For small and medium-sized high-speed engines with an output power range between 500 kW and 2000 kW, the gas mixer based ARTEMIS version is best suited in terms of costs and conversion ratio. A high-precision gas metering unit operates at its core, which accurately controls the gas flow under all ambient conditions and ensures an optimal diesel substitution rate at any load.

Illustration of the ARTEMIS Dual-Fuel System

ARTEMIS Dual-Fuel Components

| Component | Description |

ECU |

highly efficient ECU featuring

|

Gas mixer |

gas mixers delivering very homogenous gas/air mixture over the speed and load range, pressure drop maintained to a minimum thanks to the Venturi insert |

Throttle valve and Positioner |

throttle valve with integrated positioner for soft switching to dual-fuel mode and for precise control of gas flow |

| Sensors | for pressure and temperature monitoring (gas, air, cooling water, exhaust) |

Software DcDesk |

Window’s based software for configuration, parameterization and programming of HEINZMANN controllers, providing manifold graphics, printouts and data records Parameters of the control device may be adjusted during operation and the response can be monitored directly. |